Our advanced physical vapor deposition technology produces highly conductive metal films with resistivity ratings consistently below one ohm per square. We specialize in copper base layers protected by aluminum or nickel chrome top coats, creating multi-layer shielding architectures that deliver superior electromagnetic interference protection. Unlike competitors who rely on single-layer approaches or lack process expertise, our engineering team provides the technical guidance you need to specify the right coating for your application.

Vergason Technology brings a distinctive advantage to EMI and RFI shielding that no competitor can match. We manufacture the PVD coating equipment that other shielding service providers use. This dual expertise in equipment design and coating processes gives us insights into optimization, troubleshooting, and performance that service-only providers simply cannot offer.

Our clients benefit from this unique position in multiple ways. When you work with us, you gain access to process engineers who understand shielding at the equipment level, not just the application level. We can guide you through material selection, explain why copper requires protective top coats, and help you navigate the technical specifications that many purchasing teams struggle to understand. This technical partnership approach has helped companies transition from outsourcing shielding to eventually purchasing their own systems when production volumes justify the investment.

Speed and competitive pricing separate adequate service from partnerships that accelerate your production timelines. Our standard 3-5 day turnaround outpaces competitors while maintaining the quality standards required for government and defense applications. We deliver fast quotes, typically within one business day after receiving your engineering prints and shielding requirements. This responsiveness, combined with competitive pricing and highly personalized support, makes us the preferred shielding partner for companies that cannot perform these processes in-house.

"*" indicates required fields

Get expert guidance on electromagnetic shielding solutions for your specific application. Our technical team can help you determine the optimal coating approach, material specifications, and process parameters to meet your EMI and RFI protection requirements. We work directly with your design engineers to ensure coating specifications align with performance needs.

The electronics protecting national security, saving lives, and enabling advanced technology rely on Vergason Technology's electromagnetic interference shielding. Our ITAR-registered facility serves government and defense contractors requiring confidential, secure coating processes. Medical device manufacturers trust our FDA-compliant capabilities for patient-critical equipment where electromagnetic compatibility directly impacts safety and efficacy.

We provide EMI and RFI shielding solutions for:

Each application presents unique electromagnetic interference challenges. Following NDA execution, our technical team works directly with your design engineers to understand frequency ranges, environmental exposure, and precise shielding specifications. This collaborative approach ensures your coating addresses actual performance requirements rather than generic specifications.

Many companies seeking EMI shielding services face a fundamental challenge. Their purchasing teams receive shielding requirements but lack the technical knowledge to specify appropriate coating processes. Design engineers understand the electromagnetic performance needed but may not know which materials or layer combinations achieve those results. Vergason Technology bridges this knowledge gap.

We educate customers throughout the quoting and coating process. When a customer requests copper shielding without understanding oxidation concerns, we explain why an aluminum or nickel chrome protective layer is essential for long-term performance. When specifications seem unclear, we work directly with design engineers to clarify requirements and recommend optimal coating architectures. This technical partnership approach has solved complex shielding challenges across defense, medical, and industrial applications.

Our process development capabilities extend beyond standard coating recipes. We have engineered multi-layer solutions for government applications, developed specialized processes for medical device manufacturers, and created custom coating specifications that eventually led customers to purchase their own equipment. One medical device manufacturer worked with our coating services for years before their production volumes justified investing in an in-house system, which we then supplied and supported.

Speed matters when production schedules and prototype testing timelines drive your business. Our standard 3-5 day turnaround for EMI shielding coatings keeps your projects moving forward. We provide quotes within one business day after receiving engineering prints and shielding requirements, allowing you to make informed decisions quickly. This responsiveness, combined with competitive pricing that addresses the primary concern of most customers, makes us the practical choice for companies evaluating shielding service providers.

Confidentiality is not optional in our industry. Approximately 95% of our EMI and RFI shielding projects require non-disclosure agreements. Our ITAR registration enables us to handle controlled defense-related technical data with appropriate security measures. We understand that you cannot share customer names, product specifics, or detailed processes. Our secure facility and established NDA protocols protect your intellectual property and meet the stringent confidentiality requirements of government and defense contractors.

Beyond coating services, we offer post-coating assembly for customers who need components prepared for final integration. This optional service reduces your handling time and can streamline your production process for a nominal charge. From initial inquiry through final delivery, our personalized support ensures you receive not just coatings, but solutions tailored to your manufacturing requirements.

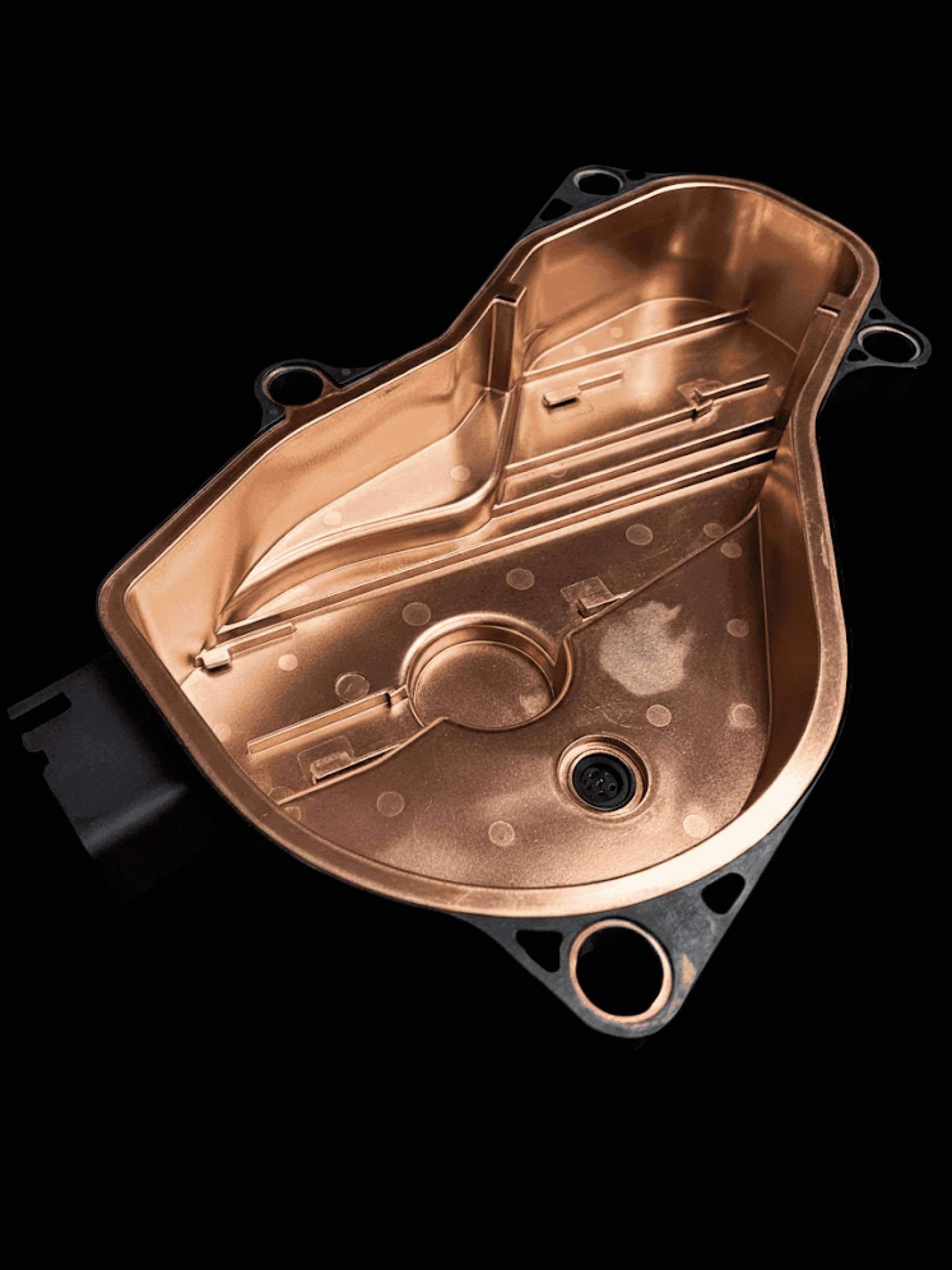

Effective EMI and RFI shielding depends on selecting the right materials and applying them with precise process control. Our PVD sputtering technology deposits copper, aluminum, and nickel chrome in configurations optimized for your specific shielding requirements. The most common architecture uses a copper base layer for superior conductivity, protected by an aluminum top layer that prevents oxidation and maintains performance over time.

Copper provides the highest electrical conductivity of common shielding materials, making it ideal for applications requiring maximum EMI protection. However, copper exposed to air oxidizes, degrading its conductive properties. This is why we typically apply an aluminum protective layer over the copper base. Aluminum resists oxidation while maintaining excellent electrical properties. For applications with specific environmental or performance requirements, nickel chrome offers alternative protective properties.

Our PVD sputtering process deposits these materials in precisely controlled thin layers. Unlike thick coatings that add unwanted weight and alter part dimensions, our nanometer-scale films provide necessary electromagnetic interference protection while maintaining design tolerances. This makes PVD ideal for plastic electronic enclosures where designers specify plastic over metal to minimize weight and reduce costs. The coating conforms to complex geometries and reaches hard-to-access areas where electromagnetic protection is most critical.

Electromagnetic interference shielding for government, defense, medical, and aerospace applications demands more than technical performance. It requires documented compliance with industry regulations, military specifications, and quality standards that protect both manufacturers and end users. Vergason Technology maintains the certifications and registrations that enable us to support your most demanding compliance requirements.

Our ISO 9001:2015 certification ensures consistent, repeatable coating processes across every production run. This quality management system provides the documentation, traceability, and process controls that regulated industries require. We inspect all orders upon receipt, perform in-process monitoring throughout the coating cycle, and conduct final testing before shipment. This systematic approach to quality assurance gives you confidence that each coated part meets specified requirements.

ITAR registration enables us to handle controlled technical data and work with defense contractors on classified projects. Many government and military shielding applications involve sensitive information that requires secure facilities and cleared personnel. Our ITAR compliance, combined with established NDA protocols, protects your intellectual property while meeting Department of Defense security requirements. RoHS compliance ensures our processes and materials meet European restrictions on hazardous substances, critical for companies serving global markets.

For medical device manufacturers, FDA compliance requirements add another layer of regulatory complexity. Our coating processes align with FDA quality system regulations and can support your device validation activities. We understand that medical applications demand rigorous documentation, and our quality systems provide the traceability you need for regulatory submissions and audits.

Government and defense contractors often face specific shielding performance criteria tied to military standards and procurement requirements. While exact specifications vary by application and remain confidential under NDA, we ensure coating thickness, conductivity, and material composition align with your required shielding effectiveness. Our technical team works with your engineers to verify that our processes meet applicable MIL-SPEC requirements and government testing protocols.

Many companies begin with coating services and transition to equipment ownership as their production volumes grow. This natural progression reflects the economics of high-volume manufacturing, where the cost per part decreases significantly with in-house capabilities. Vergason Technology supports both paths, providing the flexibility to start with services and scale to equipment when your business justifies the investment.

A medical device manufacturer serves as an excellent example of this transition. They relied on our EMI shielding services for years, outsourcing coating while focusing on their core competencies in device design and manufacturing. As their production volumes increased, the economics shifted toward in-house coating. We worked with them to specify, install, and support a PVD system tailored to their specific shielding applications. This progression demonstrates how coating services can validate processes before capital equipment investment.

Our unique position as both equipment manufacturer and service provider creates distinct value for customers. When you work with our coating services, you gain insights into process parameters, cycle times, and coating specifications that inform future equipment decisions. If you eventually purchase a system, you work with engineers who already understand your application. This continuity reduces implementation risk and accelerates the path to full production.

Starting an EMI or RFI shielding project with Vergason Technology follows a straightforward process designed to protect your confidential information while moving quickly to quotation and production. Most projects require a non-disclosure agreement as the first step. Given that approximately 95% of our shielding work involves proprietary designs or government-related applications, NDA execution protects both parties and enables detailed technical discussions.

After NDA completion, provide us with engineering prints showing part geometry and dimensions, along with your shielding requirements and specifications. These documents allow our engineering team to develop the appropriate coating process and generate an accurate quote. We typically provide quotes within one business day, addressing the most common question we receive from prospects. Without prints and requirements, we cannot estimate costs, but with proper documentation, we respond quickly.

Following quote approval, coating production typically takes 3-5 days. This standard turnaround keeps your project on schedule without sacrificing quality or precision. For customers requiring post-coating assembly services, we can provide that additional support to streamline your production process. Throughout the engagement, you work with a dedicated team that understands your application and can answer technical questions that arise during development or production.

Electromagnetic interference occurs when electrical circuits experience disruption from external electromagnetic sources. Both natural and man-made electromagnetic fields create EMI that can affect any electronic device. The consequences range from minor performance degradation to catastrophic system failures, making professional electromagnetic shielding essential for reliable electronics in critical applications.

Medical equipment affected by RFI interference can provide incorrect readings or fail during critical moments. Military communication systems disrupted by electromagnetic interference compromise mission effectiveness. Industrial process control systems experiencing EMI can cause production disruptions or safety incidents. The cost of field failures, whether measured in warranty claims, liability exposure, or mission failure, always exceeds the investment in proper EMI and RFI protection.

Professional shielding coating services provide electromagnetic protection without the capital investment, process development time, and technical expertise required for in-house capabilities. Many companies lack the specialized PVD equipment and process knowledge needed for effective shielding. Outsourcing to an experienced provider like Vergason Technology gives you access to proven processes, regulatory compliance, and technical support that would take years to develop internally.

Understanding how electromagnetic interference shielding works helps engineering teams make informed decisions about coating specifications and material selection. The fundamental principle involves blocking offending EMI before it reaches sensitive electronics inside the enclosure. Highly conductive materials like copper and aluminum absorb the electric field in the EMI, converting electromagnetic energy into kinetic energy within the metallic coating.

Our PVD sputtering process deposits these conductive metals in precisely controlled thin layers. The sputtering technique uses energized plasma to eject atoms from a target material, which then deposit onto your parts in a highly controlled vacuum environment. This atomic-level deposition creates uniform, dense coatings that conform to complex geometries and reach areas that other coating methods cannot access effectively.

The typical EMI shielding architecture starts with copper for its superior electrical conductivity. Copper's low electrical resistance makes it the most effective common material for blocking electromagnetic interference. However, copper oxidizes when exposed to air, forming copper oxide that significantly reduces conductivity over time. To prevent this degradation, we apply an aluminum protective layer over the copper base. Aluminum naturally forms a thin, stable oxide layer that actually protects the underlying metal while maintaining excellent conductive properties.

This multi-layer approach provides both immediate shielding effectiveness and long-term performance stability. The copper delivers maximum EMI protection, while the aluminum ensures that protection persists throughout the product's service life. For applications with specific environmental exposures or unique performance requirements, nickel chrome coatings offer alternative protective properties. Our engineering team can recommend the optimal material combination based on your operating conditions and shielding specifications.

Ready to protect your electronics with industry-leading EMI and RFI shielding? Request a detailed quote for your coating project. Provide your engineering prints and shielding requirements, and we will respond within one business day with pricing, lead time, and technical recommendations based on your specifications. NDA execution available upon request.