The SuperChrome 660 PVD system is optimized for reactive sputtering of VTI’s proprietary SuperChrome PVD coating. It is also capable of sputter deposition substrates with metals such as chromium, aluminum, brass, copper, stainless steel, nickel-chrome alloys, etc.

SuperChrome PVD coating has all of the benefits of decorative chrome plating, without the harmful hexavalent chromium (Cr +6) compounds. Unlike conventional PVD coatings, SuperChrome requires no clear protective top-coat to interfere with the chrome finish. In addition, this resilient sputtering deposition coating meets or exceeds the demands of the automotive, appliance, and sanitary industries yet provide the rich quality appearance required for decorative coating applications. SuperChrome PVD coating has excellent adhesion on thermoplastic substrates, making it the preferred alternative for decorative plating on plastic

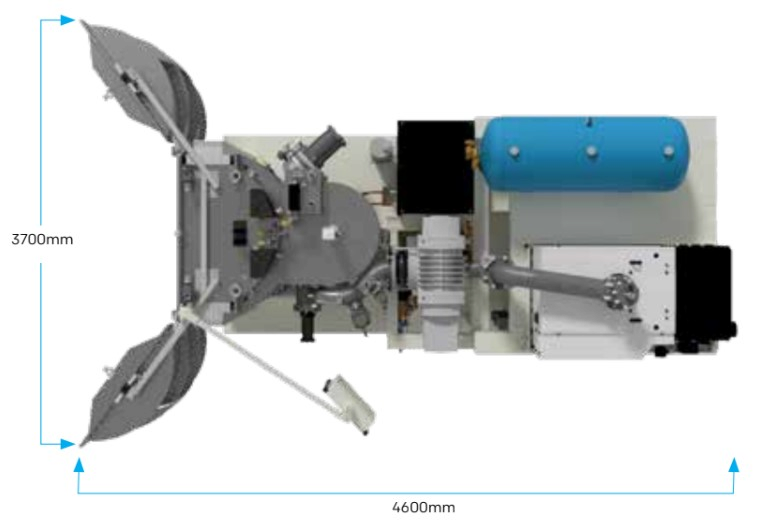

Exceptionally fast processing cycles are achieved using the finest pumping components coupled with the unique

concept of power venting, which utilizes pressurized desiccant-dried air to vent the chamber. The optional environmentally controlled enclosure at the load/unload station will further improve throughput in humid conditions.

Each system offers the ability to sputter a variety of metals, while incorporating plasma etching and plasma polymerization of base and top coats. The user can select any sequence depending on the application.

Designed with operator and maintenance access in mind, the PS4000SL allows quick and easy visual and mechanical access to all key system components. Elimination of unnecessary decorative panels creates an open route for maintenance and inspection activities.

Our technical support portfolio includes installation, operator training, process engineer training, Internet based service access, troubleshooting, and fast on-site assistance.

Excellent adhesion on plastics

No hexavalent chromium compounds (CR+6)