Examples of challenging projects include:

- Replacement of hexavalent chrome plating on plastics for automotive, appliance, and sanitary applications. (SuperChrome® PVD Coating patented in 20 countries)

- Yellow, green, and blue PVD colors for a sporting goods product

- Radar transparent metallic coatings for automotive Advanced Driver Assist Systems (ADAS)

- Non-Conductive Vacuum Metalized coatings (NCVM)

- Semitransparent metallic coatings for backlit applications

- 10-layer 25-micron thick metallic EMI shielding coating for military application

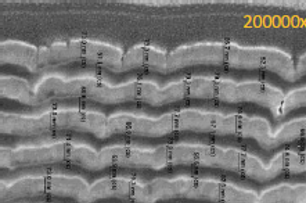

- 80-layer 8-micron thick metallic coating on extremely low temperature polymer

We perform the development in-house then transfer to our customers:

- Black chrome decorative coating for automotive trim

- Deep cavity reflectors for EV forward lighting

- Protected silver reflectors