Welcome to Vergason Technology, where performance meets precision in the world of forming and molding applications. As a leader in advanced PVD (Physical Vapor Deposition) coating technologies, Vergason understands the rigorous demands placed on forming and molding tools. Whether in cold forming, hot forming, or plastic injection molding, the right surface coating makes a measurable difference in tool life, performance, and part quality.

Our PVD coating systems are engineered to deliver exceptional wear resistance, thermal stability, and reduced friction—all while extending the service life of critical tooling components. Manufacturers across a variety of sectors rely on our innovative solutions to boost efficiency, reduce maintenance, and enhance finished product consistency. Explore how PVD coatings from Vergason can revolutionize your forming and molding operations with unmatched durability and precision.

Cold Forming Tools

- Blanking dies

- Punches

- Cold extrusion dies

- Thread rolling dies

Hot Forming Tools

- Forging dies

- Hot extrusion tools

- Hot press forming dies

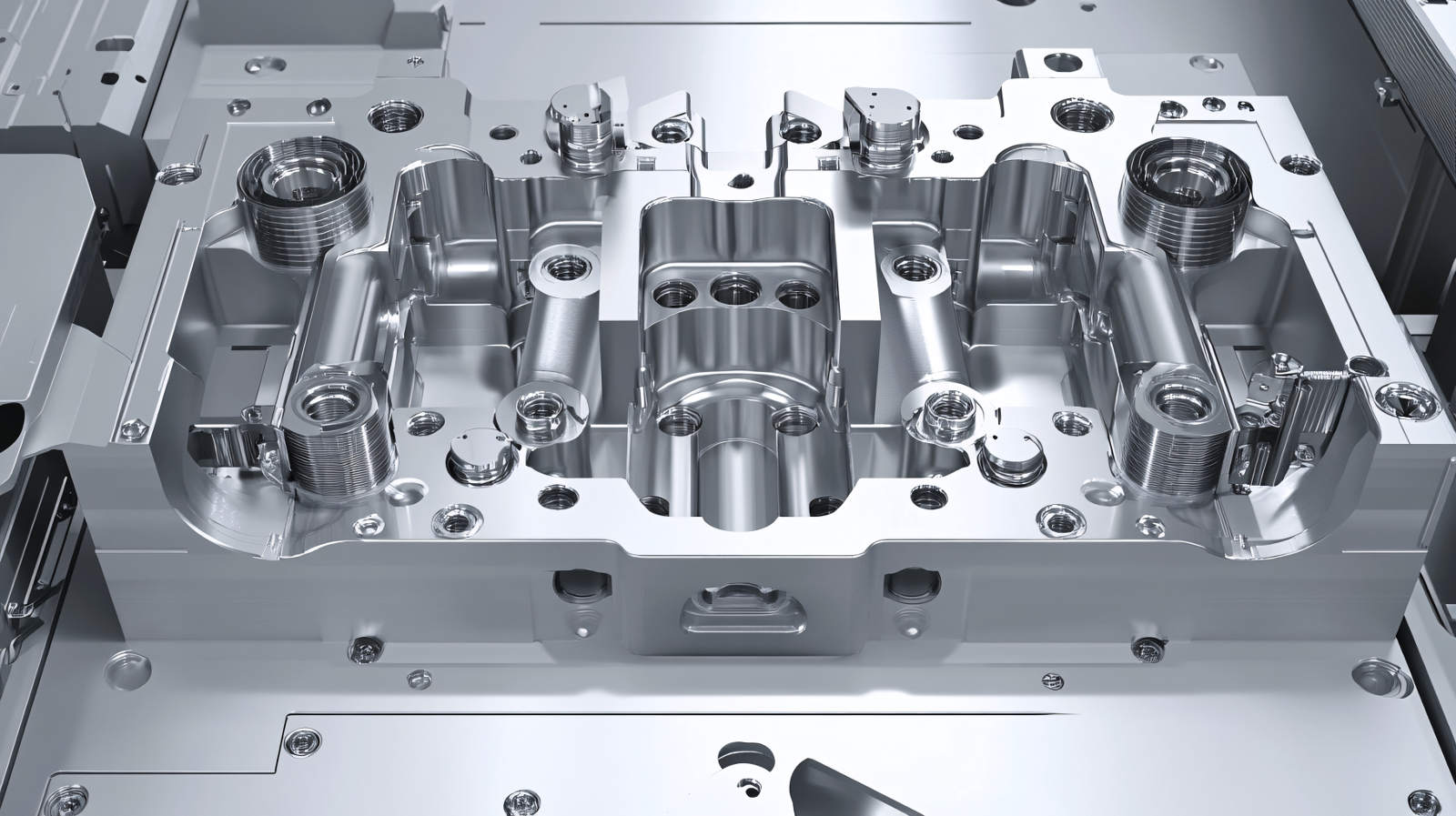

Plastic Molding Tools

- Injection molds

- Compression and transfer molds

- Mold cavities and cores

- Runners and gates

Other Forming & Molding Components

- Rolls and forming wheels

- Deep drawing tools

- Press brake tooling

- Insert components and sleeves