Fast, consistent cycles and premium coating film quality are trademarks of VTI PVD equipment.

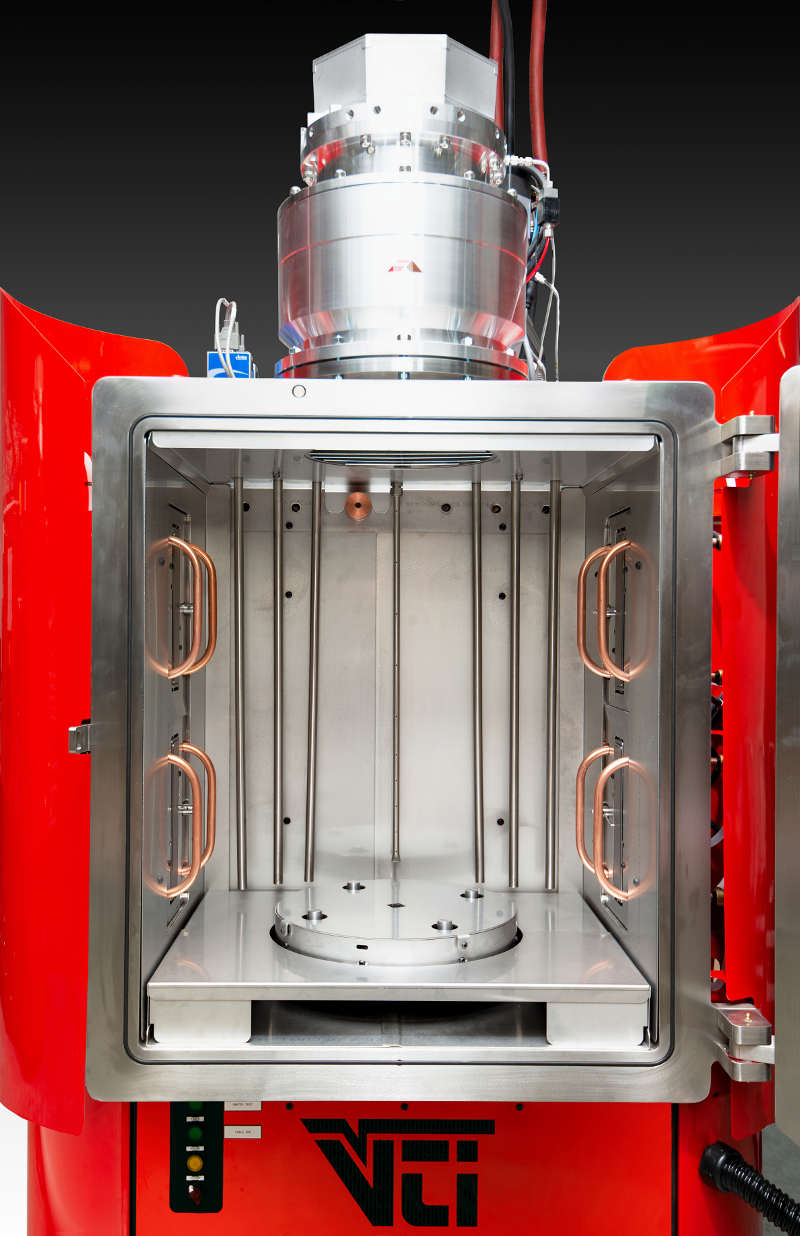

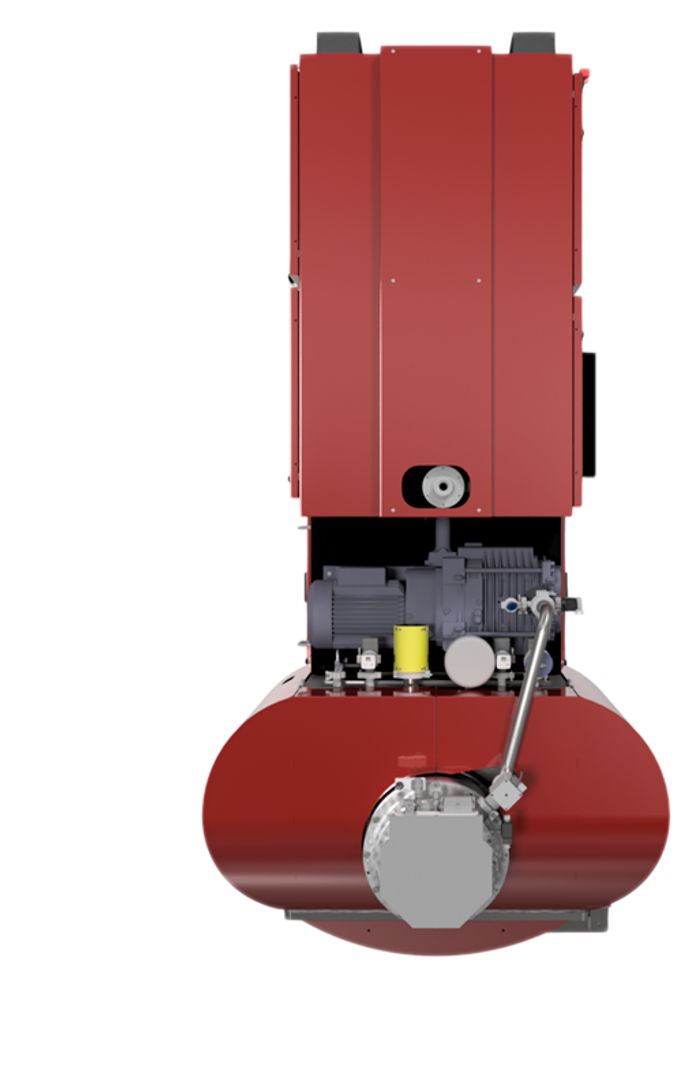

The latest innovative equipment design from VTI. The CatArc 3036 is a small footprint, high throughput design featuring our patented switched-arc deposition technology. Designed for industry, this platform will provide steady, repeatable processes for the demanding user. Ease-of maintenance is a designed-in consideration, with key components easily accessible. A robust Arc-Enhanced Glow Discharge device ensures adequate parts etch prior to deposition. The on-board Industrial PC/user interface allows for in-depth process diagnostics, system status, data acquisition, and process recipe development/modifications.

A state-of-the-art PVD coating system for industry:

Ergonomic Design