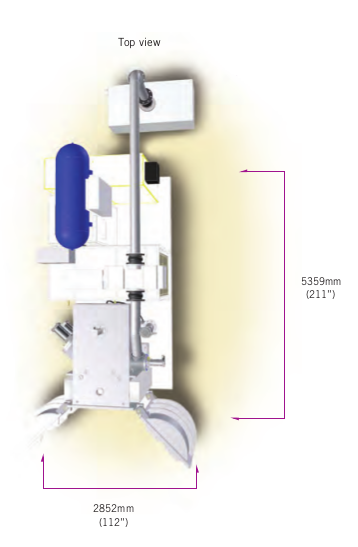

The PS4000 SL is the global performance leader in Press-Side® Rapid Cycle Metalizing. VTI pioneered the concept of locating the smaller batch, rapid cycle sputtering system in synchronous flow with the injection press. This innovation reduces scrap from excessive parts handling, and improves parts quality due to the superior film characteristics of magnetron sputtering. Introduced in 2001, the first generation of the PS4000 SL set a new standard for quality and throughput in vacuum metalizing. The current third-generation system incorporates the latest technical advances while preserving the ease of use and maintenance that made the PS4000 SL the best selling system of its kind in the world. VTI engineered the PS4000 SL to master the rigorous demands of continuous high-volume production. The two-door chamber configuration allows one door mounted part fixture to be loaded and unloaded outside the chamber, while the other door-mounted fixture is undergoing the metalization process. Major components are designed for easy access, simplifying routine preventative maintenance. Our modular design concept allows us to quickly modify the PS4000 SL configuration to meet your specific requirements. Select manual or automated door operation, choose from different pump manufacturers, robotic interface configurations, and even select a preferred programmable logic control or industrial PC. Working one-on-one with each client, the VTI team custom engineers each system to your precise specifications.

Exceptionally fast processing cycles are achieved using the finest pumping components coupled with the unique

concept of power venting, which utilizes pressurized desiccant-dried air to vent the chamber. The optional environmentally controlled enclosure at the load/unload station will further improve throughput in humid conditions.

Each system offers the ability to sputter a variety of metals, while incorporating plasma etching and plasma polymerization of base and top coats. The user can select any sequence depending on the application.

Designed with operator and maintenance access in mind, the PS4000 SL allows quick and easy visual and mechanical access to all key system components. Elimination of unnecessary decorative panels creates an open route for maintenance and inspection activities.

Our technical support portfolio includes installation, operator training, process engineer training, Internet based service access, troubleshooting, and fast on-site assistance.

Capable of sputtering a wide range of base metals and alloys

Our breakthrough Press-Side® concept streamlines the production flow while reducing scrap rates by up to 10 times