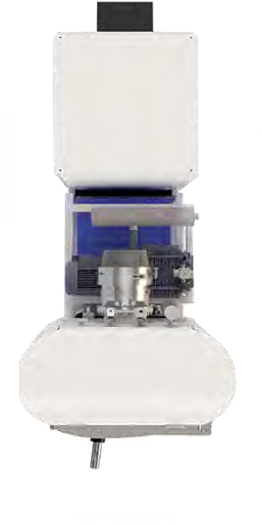

VTI introduces the CatArc ® 2500.

With two vertically adjustable coating zones, this system uses two VTI-patented switched-arc 2” X 10” (51mm x 254mm) cathodes.

The CatArc® 2500 is an affordable alternative to outsourcing your Physical Vapor Deposition (PVD) coatings. VTI delivered the first rapid cycle coating system in 1989, forging the genre of Lean PVD processing equipment. By minimizing work-in-process and maximizing continuous product flow, VTI improves quality, cost efficiencies and proves that bigger is not always better. This is exactly what the CatArc® 2500 PVD Coating System delivers. Due to differences in part design, geometry, orientation, and thermal properties, large batches can present serious challenges to operating an efficient coating line. Our innovative combination of rapid cycles and small batch sizes has created a revolutionary solution for coating and optimization. The modular design allows us to configure the CatArc® 2500 to meet your requirements. The CatArc® 2500 takes up less than 45 square feet of floor space (4 square meters), making it ideal for small manufacturing areas. Best of all, aggressive pricing enables more users to enjoy the benefits of equipment ownership. Many companies that previously could not justify the high capital investment for competing systems can now bring PVD coatings in-house.

Fast pumping cycles utilize the industry’s finest Edwards Dry Star rotary screw and Agilent turbomolecular pumping packages.

Largest coating zone with the smallest foot print of any industrial PVD coating system on the market today

Custom configurations are easily accommodated through our modular design approach. We can design the system to match your process, and assist with integration into your production facility.

Complete process includes installation, operator training, process engineer training, fixturing assistance, internet based service access, troubleshooting, and fast on-site assistance.

Easy access to sources, tooling, and rotary feed-through assembly

High efficiency vacuum pumping system with optional gate valve

Your company, technicians, engineers, and customers can rely on the CatArc® 2500 for years of reliable service.

User-focused design provides easy access to all components, minimizing down time for routine maintenance.

Smaller batches and rapid cycles allow more runs per day. This in turn makes it easier to optimize batch loading for each type of part.

Switched-arc sources deposit smoother films than conventional arc coatings due to the reduction of macro-particle inclusions.