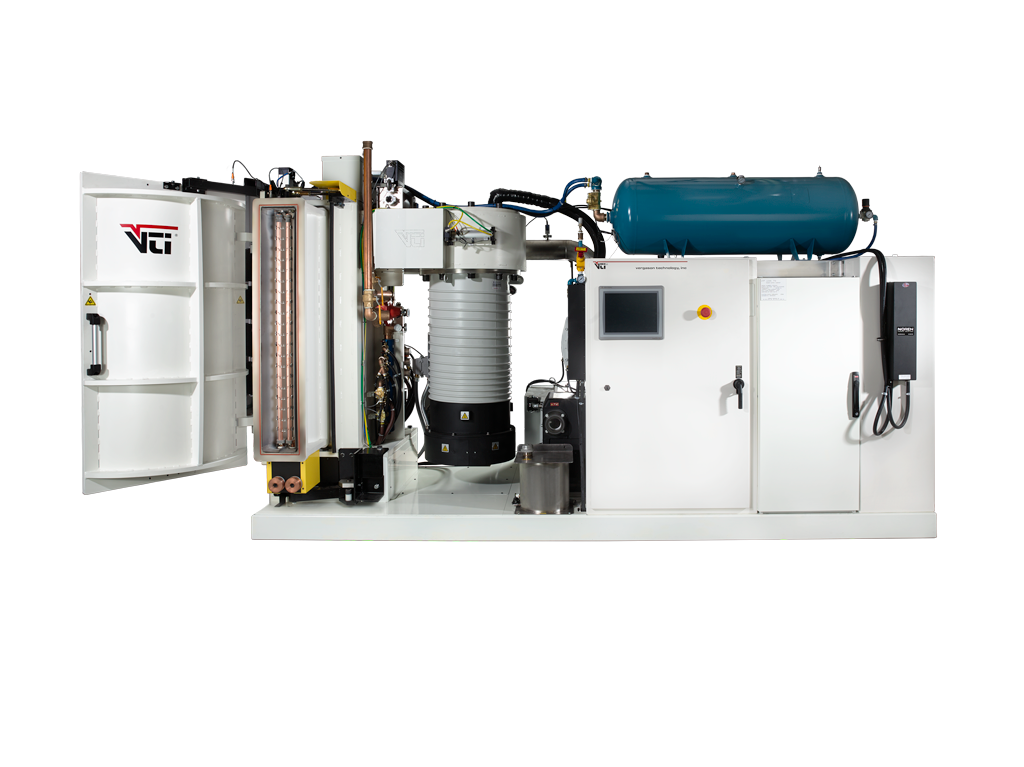

TS VTI designs, builds, sells, and services vacuum coating machines, technology, and equipment for multiple industrial applications. We offer PVD systems based on magnetron sputtering, thermal evaporation, and cathodic arc deposition. We also offer coating services for those companies who prefer to outsource their coating needs. Our coating services are primarily used for LED reflectors, EMI-blocking PCB enclosures, cutting & forming tools for machine shops, and FDA-approved coatings for medical instruments.

TS VTI maintains a diligent focus on ISO 9001 standards, and that is reflected daily in the quality products and services delivered to our clients. In addition to our ISO 9001 certification, TS VTI also maintains active ITAR registration, allowing us to support the programs falling underneath the guidelines of the International Traffic in Arms regulations.

TS VTI continues after 39+ years to be the reliability and value leader for PVD equipment & services because we are different than other suppliers:

- We are the only vacuum metalizing company that builds equipment that also operates a 3-shift coating service facility with that very same equipment. This allows us to know exactly what works and what doesn’t…and to build the most robust systems in the world.

- We are process agnostic. We use whichever deposition process is best for a given application…sputtering, thermal evaporation, PECVD, cathodic arc, or automated robotic spray painting.

- We have strong process engineering and R&D teams behind the scene. Unlike others who simply offer you an empty vacuum “can”, TS VTI will deliver a turn-key coating system complete with process recipes already programmed into the PLC.

- We act as an extension of your own engineering team, but with specific technical depth in coatings. We offer sampling and process development, saving countless weeks of development on your part.

- That same process know-how is available to our coating service customers as we optimize coatings for their specific needs, such as radar transparency, EMI rejection, and many others.